Food Packing Industry in Sweden: General Informational Overview of the Sector

If you are from Sweden and speak English, you might be interested in learning more about the food packing industry. This sector usually includes structured processes for preparing, packaging and protecting food products, with a focus on hygiene, safety standards and quality systems. The information is neutral and purely educational.

The Swedish food packing industry operates within a highly regulated environment that prioritizes consumer safety and product quality. Companies across the country employ thousands of workers in facilities ranging from small-scale operations to large industrial complexes, each contributing to the nation’s robust food supply chain.

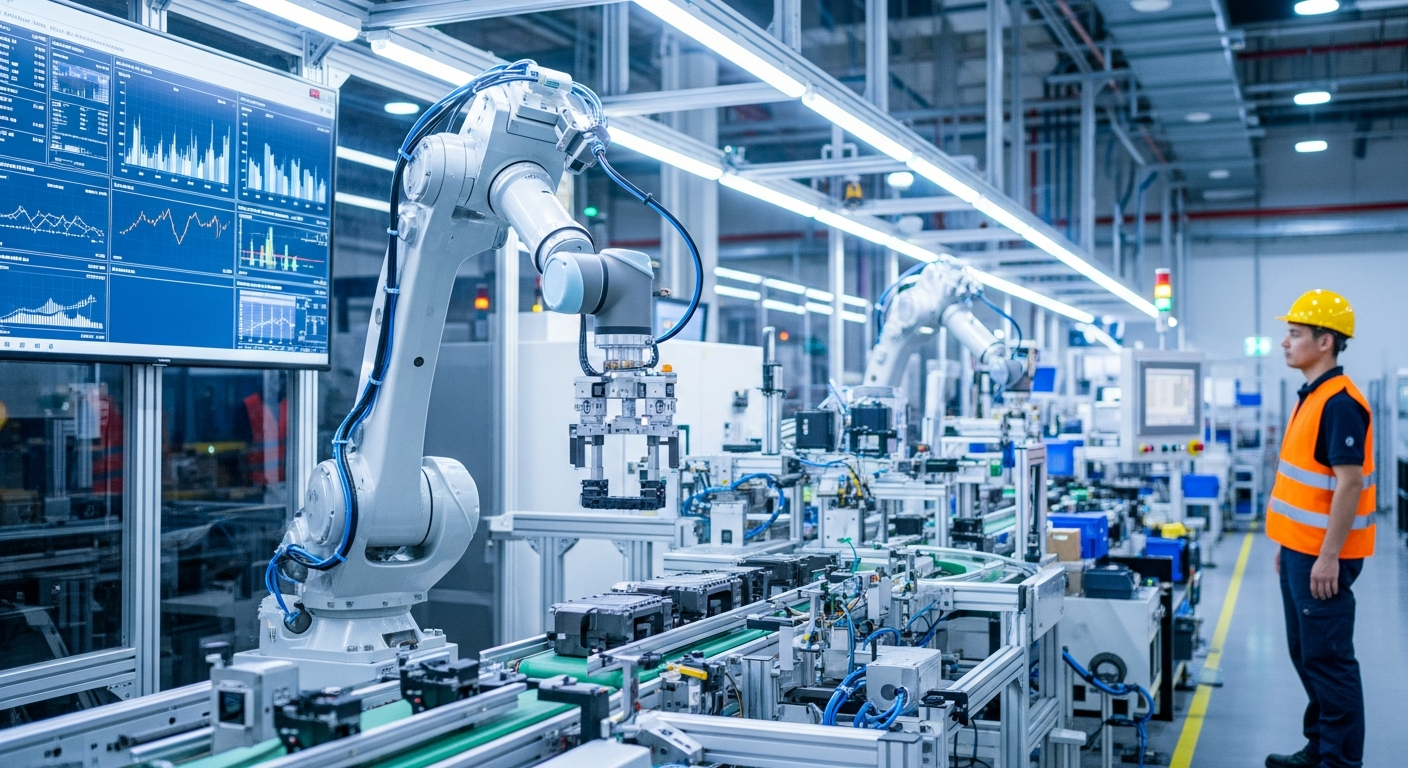

Overview of Food Packing Processes

Food packing processes in Sweden encompass multiple stages, from initial product preparation to final packaging. Primary packaging involves direct contact with food products, utilizing materials like plastic films, glass containers, and metal cans. Secondary packaging focuses on grouping primary packages for distribution, while tertiary packaging prepares products for transportation and storage. Modern Swedish facilities employ automated systems alongside manual operations, depending on product types and production volumes. The integration of technology has streamlined many processes, reducing handling time and minimizing contamination risks.

Hygiene and Safety Standards

Swedish food packing facilities adhere to stringent hygiene protocols established by both national and European Union regulations. Workers must follow comprehensive sanitation procedures, including proper handwashing techniques, appropriate protective equipment usage, and regular health monitoring. Facility design incorporates principles that prevent cross-contamination between different product areas. Temperature control systems maintain optimal conditions throughout processing and storage phases. Regular audits ensure compliance with Hazard Analysis and Critical Control Points (HACCP) principles, which identify potential risks and establish preventive measures.

Quality Control Systems

Quality assurance in Swedish food packing operations involves multiple checkpoints throughout the production process. Visual inspections detect packaging defects, product inconsistencies, and foreign material contamination. Laboratory testing verifies nutritional content, microbiological safety, and chemical composition according to established specifications. Traceability systems track products from raw materials through final distribution, enabling rapid response to quality issues. Statistical process control methods monitor production variables to maintain consistent output quality. Documentation requirements ensure comprehensive records of all quality-related activities.

Packaging and Labelling Procedures

Packaging procedures in Sweden must comply with comprehensive labelling regulations that inform consumers about product contents, nutritional information, and allergen warnings. Automated labelling systems apply information accurately and consistently across production runs. Packaging materials undergo testing to ensure compatibility with food products and compliance with food contact regulations. Sustainability considerations influence packaging choices, with many companies adopting recyclable and biodegradable materials. Portion control and package sizing align with consumer preferences and regulatory requirements for specific product categories.

Organisation of the Food Sector

The Swedish food sector organization reflects a collaborative approach between government agencies, industry associations, and individual companies. The Swedish Food Agency oversees regulatory compliance and food safety standards, while industry groups facilitate knowledge sharing and best practice development. Supply chain coordination involves close relationships between food producers, packaging companies, and retail distributors. Workforce development programs ensure adequate training for industry personnel, addressing both technical skills and safety requirements. Regional specializations have emerged based on local agricultural strengths and processing capabilities.

| Sector Component | Key Organizations | Primary Functions |

|---|---|---|

| Regulatory Oversight | Swedish Food Agency | Safety standards, compliance monitoring |

| Industry Association | Swedish Food Federation | Best practices, advocacy |

| Processing Companies | Arla Foods, Scan AB | Production, packaging operations |

| Equipment Suppliers | Tetra Pak, SIG Combibloc | Packaging machinery, technology |

| Quality Certification | KRAV, BRC Global Standards | Organic certification, quality assurance |

The Swedish food packing industry continues evolving through technological advancement and changing consumer demands. Automation technologies reduce labor intensity while improving consistency and safety outcomes. Environmental sustainability initiatives drive innovation in packaging materials and waste reduction strategies. International market expansion requires adaptation to diverse regulatory requirements and consumer preferences. The industry’s commitment to quality and safety standards positions Sweden as a reliable supplier in global food markets, supporting both economic growth and public health objectives.